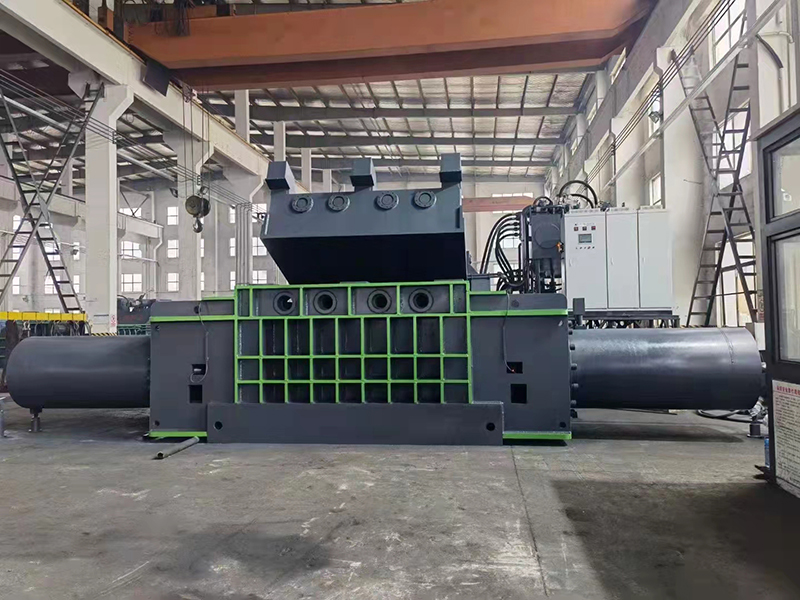

Waste Iron Baler Machine

Using the model scrap metal baler machine,which can be applied to process all kinds of scrap metal into rectangle, octagon, cylindrical shape bale, making these scrap qualified for furnace melting requirements, saving both the transportation and melting costs, increasing the melting speed and rate.to extrude various metal scraps (cuttings, shavings, scrap steel, scrap aluminum, scrap copper, scrap iron, waste stainless steel, etc.) with a thickness of less than 6 mm into various shapes of qualified materials such as cubes, cylinders and octagons. Another one is being used to scrap processing and distribution centers (bases), scrapped car dismantling and remanufacturing companies, steel and non-ferrous metals industries.to press scrap metal into edium-sized or large metal resources these metal briquettes are easy for transporting and storing in the bins as well as saving much land occupies.final shapes like such as cubes,cylinders,octagons,etcAs for these scrap materials are widely from recycling plants and metal products manufacturing factories,car dismantaling,steel plant,steel shaving,copper,rebar,scrap iron,scrap aluminum,steel mills,recycling and processing industries,non-ferrous and ferrous metal smelting industries,even including scrap yards,rolling mills, furnaces and melting units and bigger manufacturing units that generate metal scrap.color steel tiles,light and thin iron sheets, pig iron blocks, cans, beer cans,scrap aluminum flakes, scrap copper blocks, iron barrels, car shells, automobile racks, and aluminum alloy materials.

1.Stable and efficient hydraulic driving system, manual handle or PLC full automatic operation optional

2.various bale ejection methods optional, turning over, side pushing out, front pushing out, manual discharging etc.

3.various models for the custom needs: different press forces, box sizes, bale shapes

4.both electrical power and diesel engine power available

5.The technical parameters above are not binding,we reserve the right to adjust according to the actual need.

6.If you need non-standard models with different press box size,different bale size,you can call us or email us for customization.

7.Hydraulical driven with manual operation or PLC automatic control.

8.Bale-discharging:"turn-out" , "push-out" , "foward-out" & manual discharging.

9.Installation of equipment without the need for anchor bolts for easy production or equipment layout adjustment

10.Can be equipped with diesel engine as backup power supply

11.Pressing from three side,pressed bales will have a higher density

12.Simple operation, efficient and safe

|

Type |

Nominal Force (KN) |

Power (Kw) |

Feed Box Size (mm) |

Bale Size (mm) |

Productivity (Kg/h) |

Operation |

|

NKY81-4000A |

4000 |

66 |

2600*1600*1200 |

550*550 |

4000-7000 |

Manual /PLC |

|

NKY81-4000B |

4000 |

110 |

2000*1600*1100 |

550*500 |

4000-7000 |

Manual /PLC |

|

NKY81-6000 |

6000 |

135 |

5000*2000*1200 |

700*700 |

8000-10000 |

Manual /PLC |

A waste paper baling press machine is a piece of machinery used for recycling paper waste into bales. It typically consists of a series of rollers that transport the paper through a series of heated and compressed chambers, where the paper is compacted into bales. The bales are then separated from the residual paper waste, which can be recycled or reused as other paper products.

Waste paper baling press machines are commonly used in industries such as newspaper printing, packaging, and office supplies. They help to reduce the amount of waste sent to landfills and promote sustainable practices by recycling valuable resources.

The baling press for waste paper is a machine used in recycling facilities to compact and compress large amounts of paper waste into bales. The process involves feeding the waste paper into the machine, which then uses rollers to compress the material and form it into bales. Baling presses are commonly used in recycling centers, municipalities, and other facilities that handle large volumes of waste paper. They help to reduce the amount of waste sent to landfills and promote sustainable practices by recycling valuable resources

A waste paper baler is a machine used to compact and compress large amounts of waste paper into bales. The process involves feeding the waste paper into the machine, which then uses rollers to compress the material and form it into bales. Waste paper balers are commonly used in recycling centers, municipalities, and other facilities that handle large volumes of waste paper. They help to reduce the amount of waste sent to landfills and promote sustainable practices by recycling valuable resources.as more information ,pls visit us :https://www.nkbaler.com/

waste paper baling press is a machine used to compact and compress large amounts of waste paper into bales. The process involves feeding the waste paper into the machine, which then uses heated rollers to compress the material and form it into bales. Waste paper baling presses are commonly used in recycling centers, municipalities, and other facilities that handle large volumes of waste paper. They help to reduce the amount of waste sent to landfills and promote sustainable practices by recycling valuable resources.

Waste paper baling press machine is a piece of equipment used to recycle waste paper into bales. It is an essential tool in the recycling process, as it helps to reduce the amount of waste sent to landfills and promote sustainable practices by recycling valuable resources. In this article, we will discuss the working principle, types of waste paper baling press machines, and their applications.

The working principle of waste paper baling press machine is relatively simple. The machine consists of several compartments where the waste paper is fed into. As the waste paper moves through the compartments, it is compacted and compressed by heated rollers, which form the bales. The bales are then separated from the residual paper waste, which can be recycled or reused as other paper products.

Waste paper baling press machines are widely used in industries such as newspaper printing, packaging, and office supplies. They help to reduce the amount of waste sent to landfills and promote sustainable practices by recycling valuable resources. In addition, they can also help to save energy and reduce costs for businesses that use paper products.

One of the key benefits of using a waste paper baling press machine is that it can help to improve the quality of the recycled paper. By compacting the waste paper into bales, it becomes easier to transport and store, reducing the risk of damage and contamination. This makes it easier for businesses to recycle their waste paper and ensures that they are able to produce high-quality paper products

In conclusion, waste paper baling press machines are an essential tool in the recycling process. They help to reduce the amount of waste sent to landfills and promote sustainable practices by recycling valuable resources. There are two main types of waste paper baling press machines: hot-air and mechanical, and they are widely used in industries such as newspaper printing, packaging, and office supplies. By using a waste paper baling press machine, businesses can improve the quality of their recycled paper and reduce their environmental impact.